Products Details

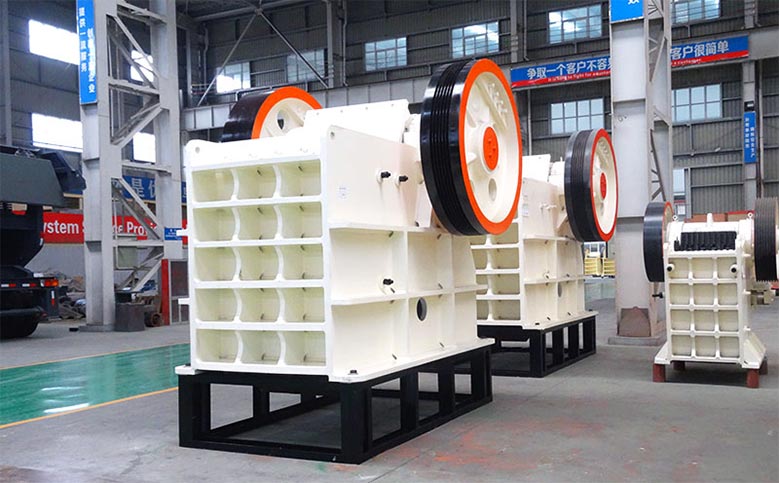

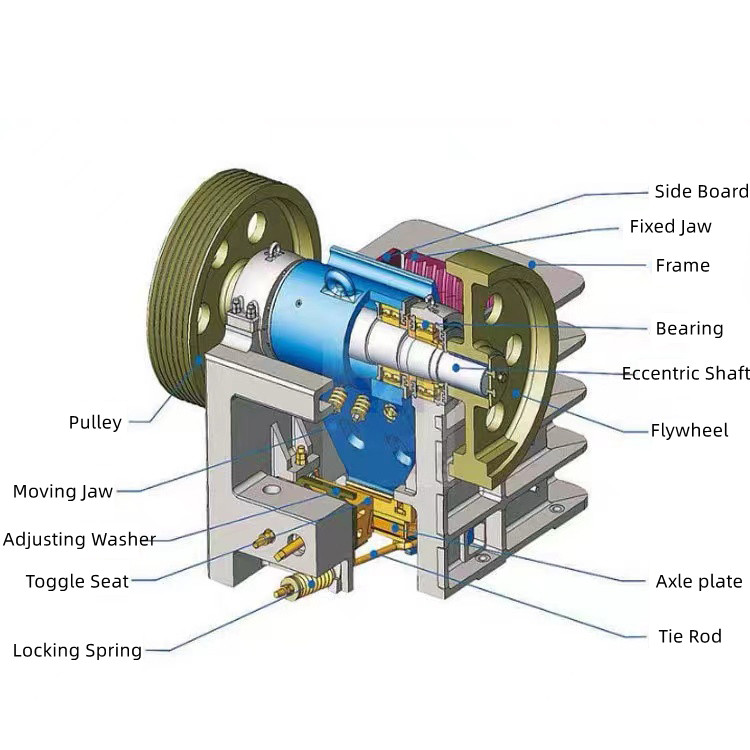

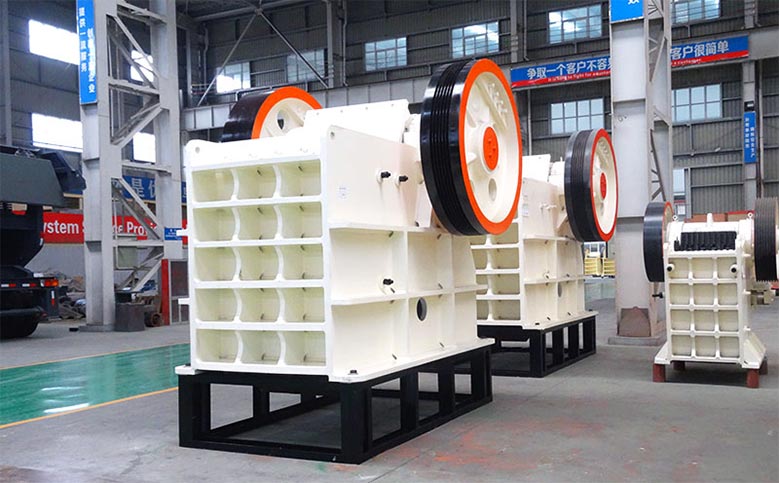

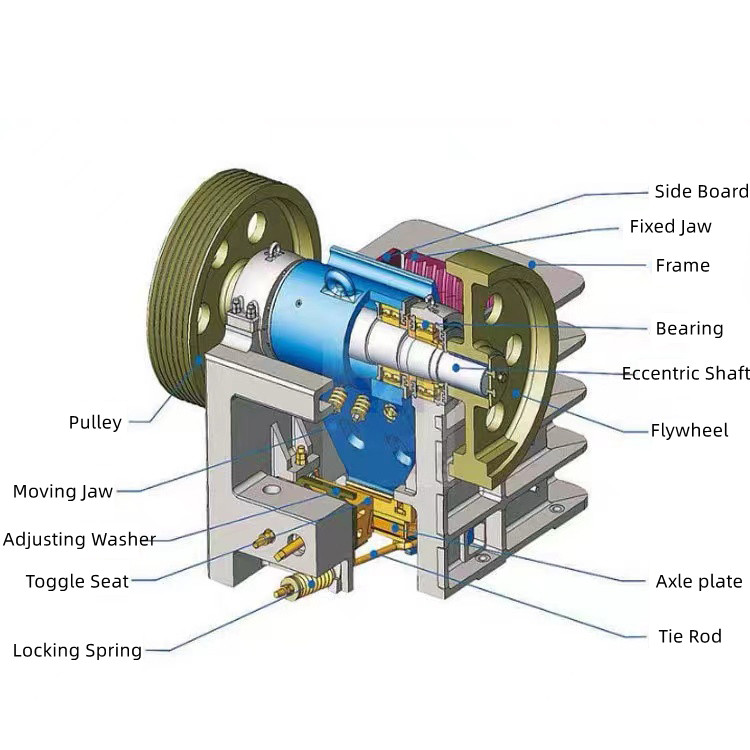

It is mainly used for medium-sized crushing of various ores and bulk materials. It can crush materials with a compressive strength not greater than 320Mpa. It can be divided into coarse crushing and fine crushing. This series of products has complete specifications, and the feeding size is 125mm~750mm, which is the first choice for primary crushing. Jaw crushers (jaw crushers) are widely used in mining, metallurgy, building materials, highways, railways, water conservancy and chemical industries. Jaw crusher operating environment: In the process of breaking large rocks into smaller ones, the first crusher is often called the "main" crusher. It is also the longest and strongest crusher in history. When feeding the jaw crusher, the material is poured from the top inlet into the crushing chamber containing the teeth. The molars push the material to the wall of the chamber with great force, breaking it into smaller stones. Supporting the movement of the teeth is an eccentric shaft that runs through the fuselage frame. Eccentric motion is usually produced by a flywheel fixed at both ends of the shaft. Flywheels and eccentrically supported bearings often use spherical roller bearings, and the working environment of the bearings is extremely harsh. Bearings must withstand enormous shock loads, abrasive water and high temperatures. Although the working environment is extremely harsh, the jaw crusher still needs to work very reliably, which is a key part to ensure efficient production. The working principle of the jaw crusher: The structure of the jaw crusher is mainly composed of frame, eccentric shaft, large pulley, flywheel, movable jaw, side guard plate, toggle plate, toggle plate back seat, gap adjustment screw, return spring, fixed jaw plate and movable jaw plate, etc. , where the bracket also plays an insurance role. The crushing method of this series of jaw crushers is the curved extrusion type. The motor drives the belt and pulley, and the movable jaw moves up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw. The plate approaches the fixed jaw plate, and at the same time the material is squeezed, rubbed, and crushed multiple times; when the movable jaw moves down, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw leaves under the action of the pull rod and spring. With the fixed jaw plate, the crushed material is discharged from the lower opening of the crushing chamber. With the continuous rotation of the motor, the movable jaw of the crusher performs periodic crushing and discharging to realize mass production.

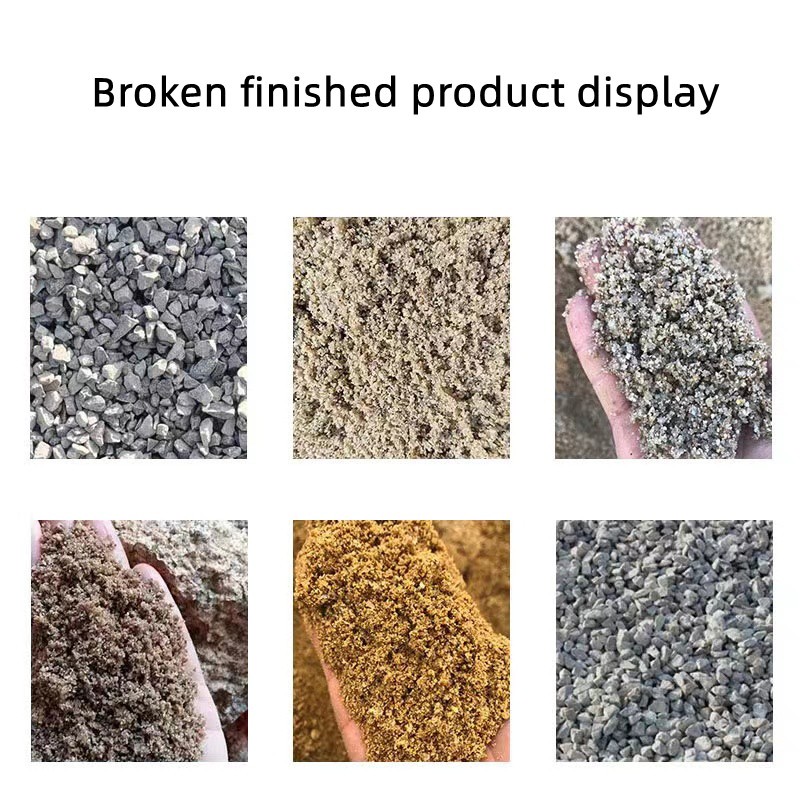

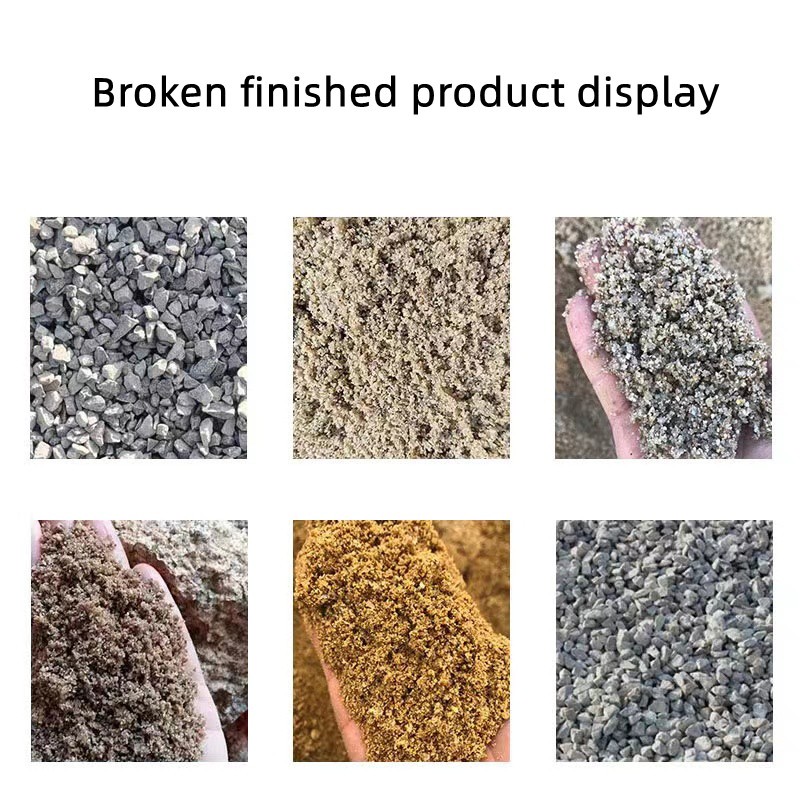

1. The crushing cavity is deep and there is no dead zone, which improves the feeding capacity and output; 2. The jaw crusher has a large crushing ratio and uniform particle size; 3. Gasket type discharge port adjustment device, reliable and convenient, with a large adjustment range, increasing the flexibility of the equipment: 4. The lubricating system is safe and reliable, the parts are easy to replace, and the maintenance workload is small: 5. The jaw crusher has simple structure, reliable operation and low operation cost. 6. Equipment energy saving: 15%~30% energy saving for a single machine, and more than double the energy saving for the system; 7. The discharge port of the jaw crusher has a large adjustment range, which can meet the requirements of different users; 8. The jaw crusher has low noise and less dust.

1. The crushing cavity is deep and there is no dead zone, which improves the feeding capacity and output; 2. The jaw crusher has a large crushing ratio and uniform particle size; 3. Gasket type discharge port adjustment device, reliable and convenient, with a large adjustment range, increasing the flexibility of the equipment: 4. The lubricating system is safe and reliable, the parts are easy to replace, and the maintenance workload is small: 5. The jaw crusher has simple structure, reliable operation and low operation cost. 6. Equipment energy saving: 15%~30% energy saving for a single machine, and more than double the energy saving for the system; 7. The discharge port of the jaw crusher has a large adjustment range, which can meet the requirements of different users; 8. The jaw crusher has low noise and less dust.

Wheel Bucket Sand Washing Machine,

Air Filter Dust Collector,

Basalt Stone Crusher Station,

China Spreader Manufacturer,

Stainless steel livestock drinking trough,

Stone Crush Screening Plant,

Horizontal Vibrating Screen,

Jaw crushers,

Cattle Feed,

Automatic animal scattering feeder,

1. The crushing cavity is deep and there is no dead zone, which improves the feeding capacity and output; 2. The jaw crusher has a large crushing ratio and uniform particle size; 3. Gasket type discharge port adjustment device, reliable and convenient, with a large adjustment range, increasing the flexibility of the equipment: 4. The lubricating system is safe and reliable, the parts are easy to replace, and the maintenance workload is small: 5. The jaw crusher has simple structure, reliable operation and low operation cost. 6. Equipment energy saving: 15%~30% energy saving for a single machine, and more than double the energy saving for the system; 7. The discharge port of the jaw crusher has a large adjustment range, which can meet the requirements of different users; 8. The jaw crusher has low noise and less dust.

1. The crushing cavity is deep and there is no dead zone, which improves the feeding capacity and output; 2. The jaw crusher has a large crushing ratio and uniform particle size; 3. Gasket type discharge port adjustment device, reliable and convenient, with a large adjustment range, increasing the flexibility of the equipment: 4. The lubricating system is safe and reliable, the parts are easy to replace, and the maintenance workload is small: 5. The jaw crusher has simple structure, reliable operation and low operation cost. 6. Equipment energy saving: 15%~30% energy saving for a single machine, and more than double the energy saving for the system; 7. The discharge port of the jaw crusher has a large adjustment range, which can meet the requirements of different users; 8. The jaw crusher has low noise and less dust.